Next Stop for Climate Action: Making Emissions Visible and Pricing Them

Unprecedented transparency is needed to visualize, track, monetize, and curtail the world’s growing methane super emissions problem.

Recent global policy convenings — from COPs in Scotland and Egypt to Climate Week in New York — have focused on methane. Remarkably, 125 countries have signed onto the Global Methane Pledge to cut emissions 30 percent by 2030. And, after a generation talking about pricing greenhouse gases, the US Congress passed a new law that puts a price tag on methane emitted by the oil and gas sector. These historic efforts are a big boost for climate action.

Methane Emissions — More Powerful Yet Undercounted

Oil and gas systems routinely leak methane, a greenhouse gas that is 100 times more powerful in warming Earth than carbon dioxide over its twelve-year lifetime. Purposeful and inadvertent releases vary in volume from flares, tanks, compressors, pipelines, and other equipment.

This is untenable. In 2021 alone, an estimated 144 billion cubic meters of gas were intentionally released through flaring — enough to generate two-thirds of the European Union’s electricity needs. In the United States, faulty flaring equipment results in methane emissions at rates five times higher than currently reported in the US Environmental Protection Agency’s greenhouse gas inventory. Despite the outsized danger to the climate, the good news is that the world has the potential to rapidly clean up methane emissions by simply detecting the leaks and allowing the markets to price costs accurately.

Making Emissions Visible

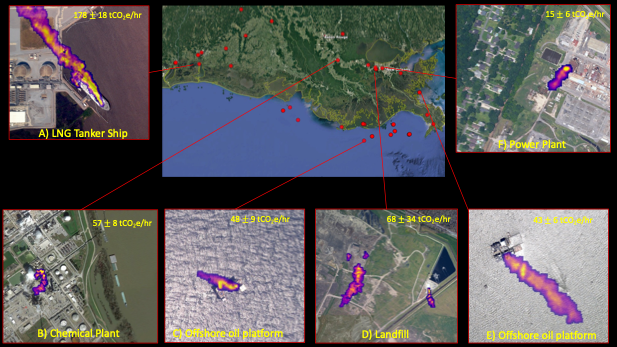

Among sources of methane emissions, super-emitters — satellite detected sources that emit over 50 kilograms of methane per hour — have an outsize impact, especially those that go undetected and persist over long periods. RMI is a partner in the Carbon Mapper Coalition, a public-private partnership led by the nonprofit organization Carbon Mapper that is tracking methane and CO2 point-source emissions from aircraft and satellites. Ongoing airborne campaigns have identified methane super-emitters in most major oil and gas producing regions in the United States. And Carbon Mapper’s reach will expand globally with Planet’s planned launch of two hyperspectral satellites in 2023. Emissions data will be free and publicly available online, providing accessibility and transparency to maximize impact.

These satellites can also spot ultra-emitters that are on the order of many tons per hour. Emissions add up quickly, especially in the near-term considering methane’s potent warming over its lifetime. If a large super-emitter persists for several months, these climate impacts can be on par with the entire US auto fleet’s annual emissions.

Source: Carbon Mapper, 2021.

Quantifying Emissions and Activating Markets

Carbon Mapper’s efforts show that wasteful companies respond when they are informed of their emissions. For example, in California, 44 companies voluntarily took corrective actions between 2017 and 2021 as a direct result of Carbon Mapper’s airborne surveys detecting methane. This prevented the equivalent of nearly five metric tons of CO2 from escaping into the atmosphere.

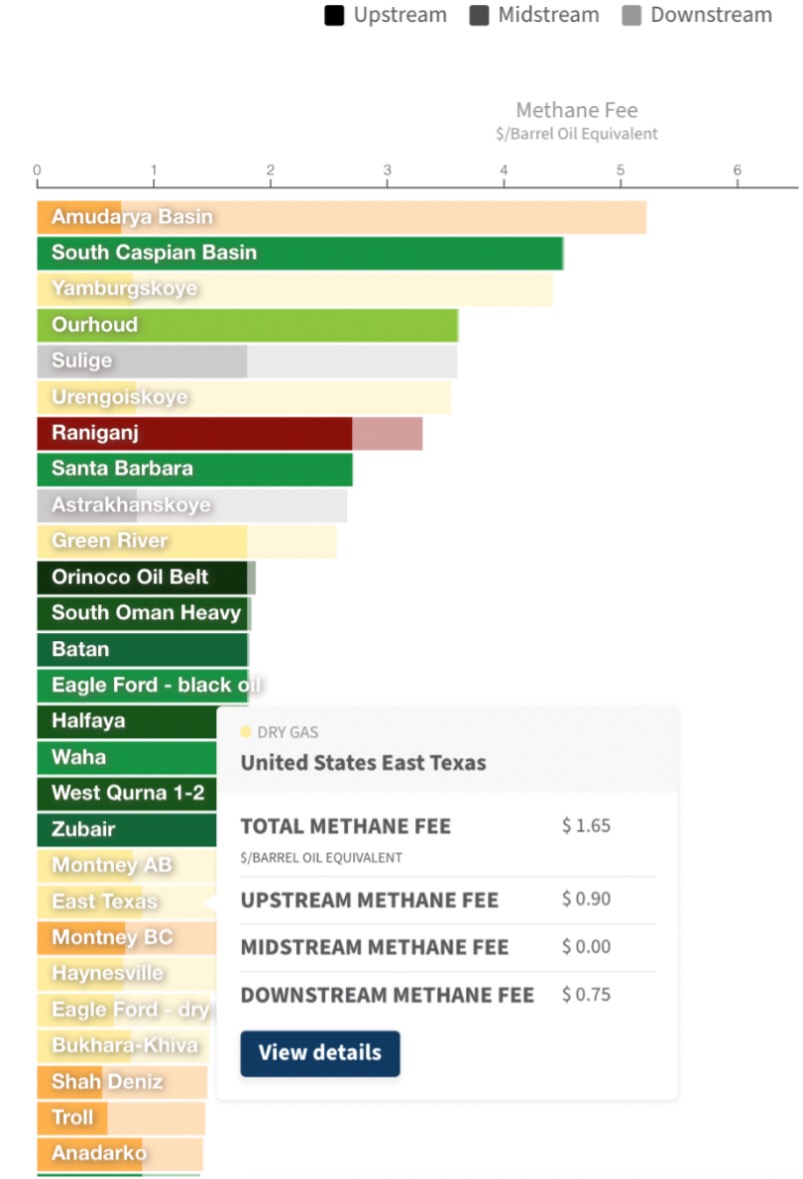

RMI’s lifecycle emissions modeling of the world’s top producing oil and gas assets can have a similar effect. Best estimates indicate that oil and gas make up over half of human-made emissions. But current inventory methods are inadequate and grossly undercount oil and gas emissions, especially from methane. RMI’s Oil Climate Index plus Gas (OCI+) assesses emissions from varying assets, providing a check and balance on self-reported emissions. In the coming months, RMI will roll out modeling of even more assets, and include additional details such as operatorship.

By assigning a shadow price on oil and gas, operators can figure leak prevention into their decision-making. And policymakers can adopt more effective climate protection. For example, the $900 per ton methane fee set under the US Inflation Reduction Act in 2024 translates into $1.85 per barrel oil equivalent on East Texas gas. Thus, this gas asset would be assessed a 30-cent shadow price over and above the $8 per thousand cubic foot market price on US industrial gas consumers — a 3.5 percent emissions penalty. Assessing methane shadow prices makes it more viable to stem leakage systemwide and activate climate markets that advance durable mitigation efforts.

This is already happening. For example, Munich Re, the world’s biggest reinsurance agency, is using the OCI+ model to assess the varying emissions for thousands of oil and gas assets it is insuring worldwide. This move is expected to result in re-insurance coverage for oil and gas projects. Moreover, Munich Re is now rethinking its financing, construction, and operation of new oil and gas fields.

Source: RMI, OCI+.

RMI’s work on emissions transparency also provides a strong foundation to advance sectoral decarbonization strategies on many fronts. We leverage our climate intelligence in combination with broad sectoral expertise to help investors maintain climate-aligned portfolios, companies convert net-zero climate commitments into actionable strategies, and governments craft informed policies and regulations. Together with RMI’s Center for Climate Aligned Finance we are working with partners to overcome barriers to climate alignment at the firm, sector, and system levels.

It is imperative that we make substantial progress toward a low-carbon economy by 2030 to prevent triggering dangerous climate tipping points. Cutting oil and gas emissions — while also reducing oil and gas demand — are both integral to any successful strategy. This involves getting major global financial institutions on track with net-zero commitments, scaling up green finance, and working in partnership to transition carbon-intensive industries to get to net zero. Making methane emissions visible and putting an accurate dollar amount on their true societal costs are essential to give us a fighting chance at avoiding the most catastrophic consequences of climate change.